.

.

Questions? PLEASE CONTACT US

.

.

Questions? PLEASE CONTACT US

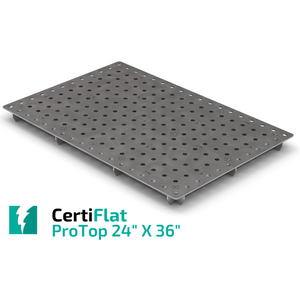

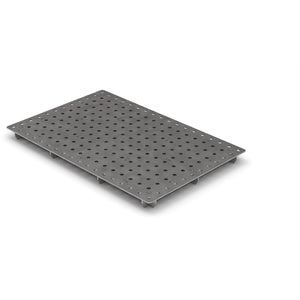

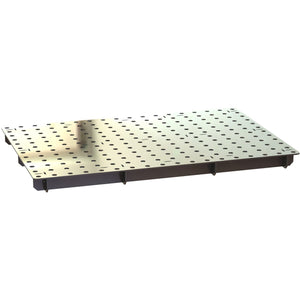

The Certiflat ProTop Welding Table - This welding table is designed specifically for welders, and is the same tables used in our shop daily and by OEM manufacturers across the USA and Canada. These kits are built with tough 3/16" hot rolled pickled & oiled steel, using state-of-the-art CNC laser cutting technology for an exceptional fit-up. Our proprietary tab & slot methodology for building stiff, accurate welding fixtures has been proven in real-world manufacturing settings for over 15 years.

Features:

Dimensions: 24" x 36" Welding Surface - 864 Sq. Inches of usable surface area.

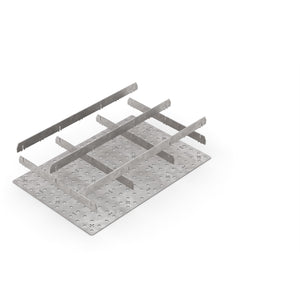

Our CNC sheet laser parts go together fast and square, using the tab and slot methodology throughout to make building a quality tool that lasts forever as simple as possible. The internal webbing works to force the table flat during assembly and keeps it that way for years of trouble-free and accurate welding. The 16mm holes on 2" centers fit most industry standard welding clamps and allow for infinite fixturing positions. Unlike other welding tables, our tops are designed and manufactured to ensure they're flat from the beginning and stay that way for the life of the tool.

Follow our assembly instructions and we guarantee your new welding table will be flat.

Assembly Video can be found here: https://www.youtube.com/watch?v=E_SyzcCzh74

Unless you are making arrangements to pick up your purchase, all items require shipping.

How much is it to ship?

Most certiflat items are very heavy. UPS has a weight limit of 150lbs.

Home based businesses and farms do not qualify for commercial status even with a forklift.

Questions?

WHAT IS THE DIFFERENCE BETWEEN THE TABLES?

-PRO Table Tops

-Mini-Block

-FabBlocks

Note: The FabBlock and mini-block have sides with our standard hole pattern, and can be expanded by either using our fabwings or by bolting multiple blocks together. The options for sizes and configurations are essentially endless with the Mini-Block and FabBlock style tables!

WHAT LEGS DO I NEED?

CAN I GET A THICKER/LARGER PRO TABLE?

WHY WOULD I WANT THREADED HOLES?

DO YOU HAVE A BEGINNER PACK/ACC PACK?

HOW DO THE FABNUTS/SPACERS WORK?

DO YOU OFFER ASSEMBLY?

WHAT IS THE LEAD TIME?

i

i i

i i

i i

iThank you for submitting a review!

Your input is very much appreciated. Share it with your friends so they can enjoy it too!

Very pleased with personal service and product. High quality welding top. I will be buying more products from this company. You will not be disappointed

Assembled well solid a As a rock

Super happy with this table. The ease of construction, coupled with the ability to keep it flat was very satisfying. Even an amateur welder like myself (haven’t welded in 20 years) I was able to weld the table flat with no fuss. Just make sure you have enough clamps. I followed the YouTube video (check for the crown before welding), and it came out near perfect. Worth every penny.

Quick shipping and nice product

I'm just a hobby welder with about 60 years' experience and this is by-far the best deal for the money. The ability to have a smooth, flat surface and fixture clamps is fantastic! Thank you!